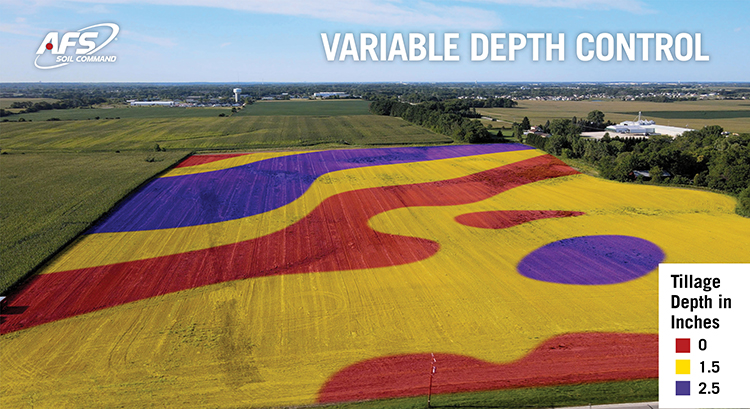

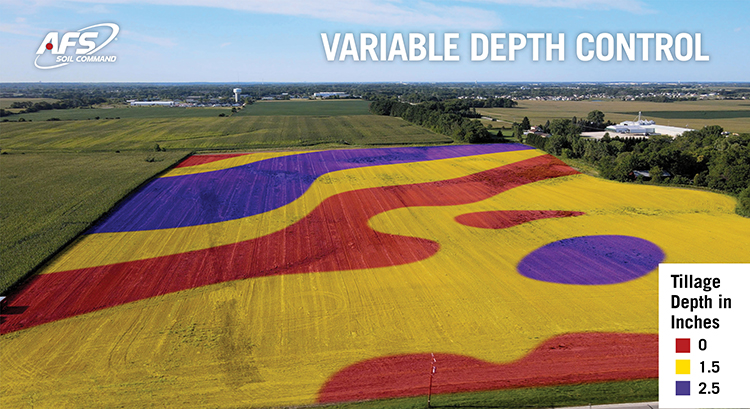

Available for fall 2021, Case IH AFS Soil Command™ tillage prescription technology enables producers to vary their tillage settings based on changing soil types, field conditions, conservation practices and topography. This allows operators to address a range of soil management challenges to make every inch of the field an optimal environment for plants and to minimize erosion and preserve moisture where needed.

Site-specific precision delivers agronomic benefits

Site-specific precision delivers agronomic benefits

Through Advanced Farming Systems (AFS) Connect™, a farm manager, consultant or agronomist can create prescription maps that enable automatic machine adjustments to help achieve changing soil goals across a field. Each aspect of the tillage tool can be assigned different prescriptions, so the entire tillage tool, not just depth, is precisely coordinated and monitored. AFS Soil Command agronomic control technology optimizes settings for depth control, fore/aft leveling, stabilizer wheel position and Crumbler® downforce.

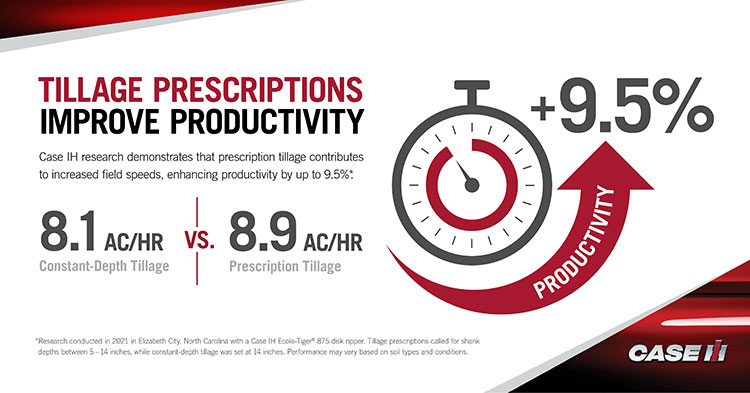

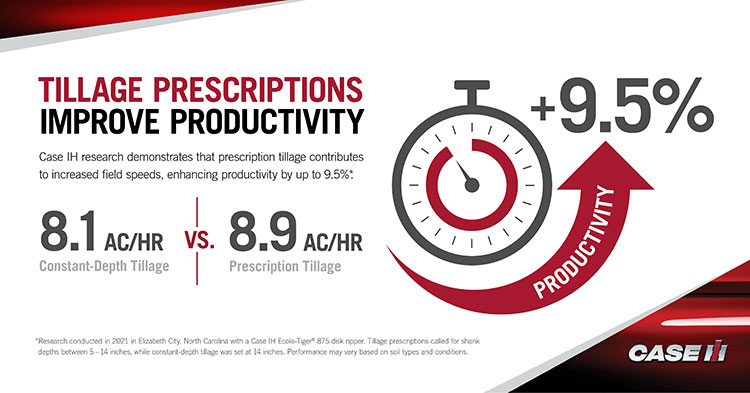

“This productivity gain can make a world of difference when operators are performing soil management in tight windows,” Lursen said. “Plus, these efficiencies can help producers get the most out of their equipment by lowering cost per acre.”

“This productivity gain can make a world of difference when operators are performing soil management in tight windows,” Lursen said. “Plus, these efficiencies can help producers get the most out of their equipment by lowering cost per acre.”

This capability completes the full suite of AFS Soil Command offerings — including seedbed sensing, agronomic control and mapping technologies — to optimize seedbed preparation for planting productivity.“Whether a grower practices conventional or conservation tillage, AFS Soil Command tillage technology is a game-changer because it brings site-specific precision to soil management.

With tillage prescriptions, we’re taking the same variable rate approach growers use for seed and fertilizer rates,” said Chris Lursen, Case IH tillage marketing manager. “Zone-managed tillage allows growers to farm for all conditions — from residue management and compaction removal to improving soil conservation.”

With AFS Soil Command™ tillage prescription technology, producers can vary their tillage settings based on changing soil types, field conditions, conservation practices and topography.

Through Advanced Farming Systems (AFS) Connect™, a farm manager, consultant or agronomist can create prescription maps that enable automatic machine adjustments to help achieve changing soil goals across a field. Each aspect of the tillage tool can be assigned different prescriptions, so the entire tillage tool, not just depth, is precisely coordinated and monitored. AFS Soil Command agronomic control technology optimizes settings for depth control, fore/aft leveling, stabilizer wheel position and Crumbler® downforce.

In Case IH research, tillage prescriptions developed based on soil type and conditions contributed to more efficient fuel economy and usage, compared with constant-depth tillage.