Larson is an associate professor and extension specialist in the department of biological systems engineering at the University of Wisconsin-Madison. Sanford is an assistant professor of agricultural and biological systems engineering at UW-Platteville and faculty researcher for the Wisconsin Dairy Innovation Hub.

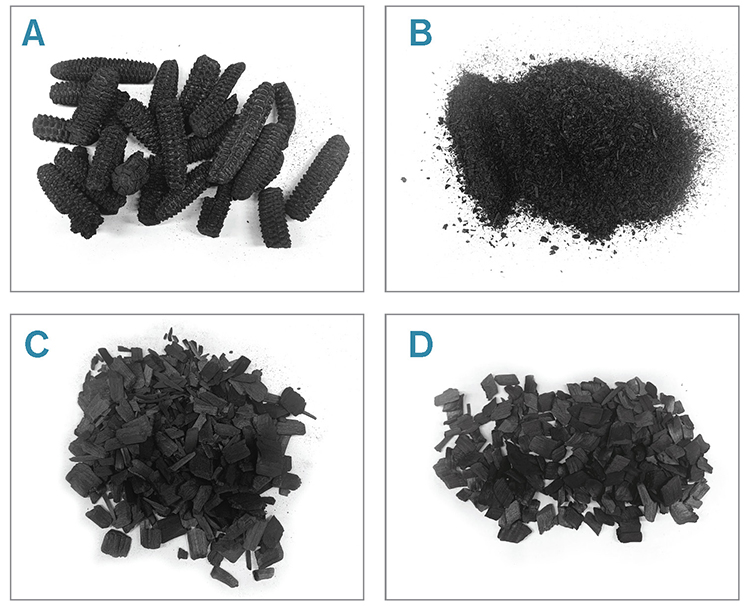

Biochar is a carbon-based product resulting from pyrolysis, where feedstocks (wood chips, corncobs, or even manure solids, for example) are heated without oxygen to high temperatures to produce oils and gas that can be used for energy. Biochar is what remains after that process.

The product contains a lot of carbon and is very low density, meaning a large bag can be very lightweight (5 to 20 pounds per cubic foot). The biochar can contain a variety of nutrients and other materials depending upon what was within the feedstocks made to create the biochar.

One of the most interesting things about biochar is the structure, which is very porous — think lots of tiny gaps or void space where air and water can move through the biochar. The structure provides a lot of places for all kinds of different molecules to bind to the biochar, allows air and water to enter, and even provides a place for microorganisms to grow. This is important because biochar characteristics can change how effective the biochar is for a particular application.

Made from manure

Characteristics vary depending upon what the biochar was produced from (the feedstock), the temperature it was produced at (300 to 800°C), and the duration it was produced, among other factors. These factors are important when starting to examine how biochar can be most effectively integrated into manure systems.

Biochar can be made from manure solids, or it can be made from other feedstocks and integrated into manure systems. Biochar can be used for a variety of applications, such as reducing hydrogen sulfide production or recovering nitrogen and phosphorus from manure streams.

Manure can be separated, and the manure solids can then be dried and converted into biochar. The resulting manure-based biochar has a significantly reduced density compared to manure. This can reduce handling and transport issues since it is lighter and takes up less space than the original manure solids, meaning more can be moved with less cost.

Unfortunately, drying manure solids is an energy intensive activity that can make the process expensive, but the availability of biogas on many farms that can be used to dry manure solids is lowering the barriers to making manure-based biochar. While much of the nitrogen can be lost in the drying and pyrolysis process, the phosphorus is retained and can be transported farther distances at the same cost compared to separated solids.

In addition, manure-based biochar poses less risk than unprocessed manure as the high production temperature inactivates pathogens and eliminates odors. While this is an area that is currently being explored, more work needs to be done to assess the economics of this process and the fertilizer or nutrient value of the biochar.

Other feedstocks work, too

Biochar can also be made from other organic feedstocks depending upon the characteristics of biochar that would be useful for a specific agricultural application. For example, some wood-based biochars were found to have the ability to reduce hydrogen sulfide production in manure-based anaerobic digesters. This could be useful in reducing this corrosive gas that also has a significant human health risk.

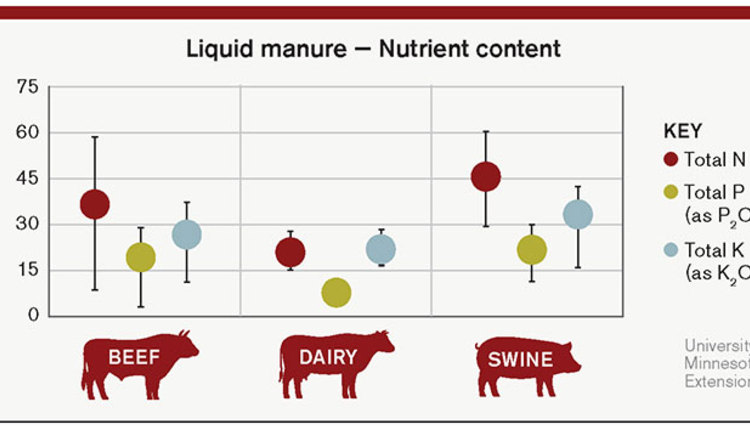

Biochar can also be used to uptake manure nutrients such as nitrogen and phosphorus. The biochar characteristics are important in terms of the nutrient type and form they can uptake. Biochar has shown ability to uptake ammonium or ammonia, where the uptake amount is generally based on the cation exchange capacity. Key factors in determining a biochar cation exchange capacity is the biochar feedstock and production temperature. However, other characteristics may be important for uptake of different forms of nutrients.

In addition, biochar can be modified to target characteristics needed for an end application, sometimes called designer biochar, as it targets a specific application. For example, allowing biochar to naturally age in soil has improved the ability of biochar to uptake nitrate. Further, cations (such as calcium) can be added to manure solids prior to pyrolysis, which has then been shown to increase the ability of the biochar to uptake phosphorus. To modify biochar, researchers have to look critically at the mechanisms behind the desired function and maximize the ability of the biochar to produce the desired effect.

Out in the field

While biochar can be produced from many different feedstocks and integrated into manure systems in different ways, almost all biochar eventually gets field applied. Biochar is known for its ability to improve soil quality. Improvements in soil water holding capacity have been measured when biochar is applied to soil systems.

When biochar is applied, it can also serve as a slow-release fertilizer. The biochar characteristics are critical for understanding application impacts to cropping systems. In many cases, the biochar can be beneficial at specific land application rates, but when overapplied, it can lead to reduced yields. Understanding the specific characteristics of the biochar will allow users to better incorporate biochar and actualize the desired benefits.

While there are many potential benefits to integrating biochar into manure systems, our knowledge is evolving rapidly as researchers continue to investigate the impacts from incorporating these products on farms.

This article appeared in the November 2020 issue of Journal of Nutrient Management on pages 18 and 19.

Not a subscriber? Click to get the print magazine.