The author is with USDA’s U.S. Meat Animal Research Center in Clay Center, Neb.

Concentrated animal feeding operations (CAFOs) are intensely managed production systems that allow for improved efficiency and better care of the animals. Manure from these systems must also be intensely managed to avoid negative impacts on the environment.

Cattle feedlot pen surfaces are particularly challenging because the manure is directly exposed to the environmental elements of rain, snow, sun, and wind. Chemical, physical, and biological reactions occur on the feedlot surface that result in the release of a variety of compounds.

Airborne pollutants from CAFOs are comprised of particulate matter, biological materials, and gaseous emissions including carbon dioxide, methane, nitrous oxide, ammonia, hydrogen sulfide, and other odorous compounds. Because of the complex reactions that occur on the feedlot surface, when conditions change to prohibit the release of one gas, it can create an opportunistic environment for a second gas to be produced. This complicates the ability of producers to manage emissions from the feedlot surface.

Into the air

Hydrogen sulfide is a colorless gas that has a characteristic rotten egg smell. It is formed during bacterial decomposition of human and animal waste and is present in emissions from sewage treatment facilities and landfills. Iowa, Minnesota, Nebraska, Rhode Island, and Texas have ambient air quality standards for hydrogen sulfide emissions from CAFOs. These standards and potential nuisance issues prompt the need for mitigation of hydrogen sulfide and other sulfides from livestock facilities.

Ammonia emissions are commonly associated with livestock production. Nitrogen losses as ammonia can be quite high from beef cattle feedlots. Research has demonstrated that 51% to 73% of the nitrogen on the cattle feedlot surface can be lost as ammonia during the summer and 35% to 50% of nitrogen is lost during winter months. This pollutes the environment and limits the fertilizer value of the cattle manure.

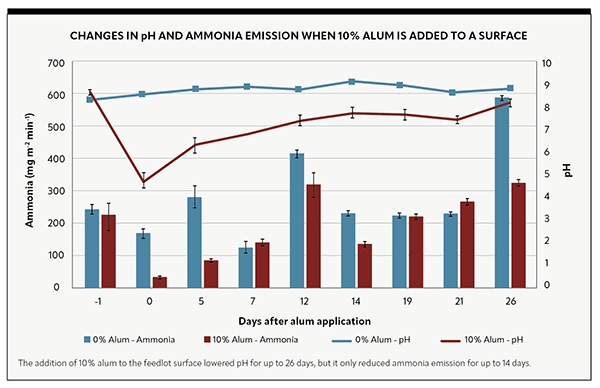

A pH of 7 to 10 is ideal for ammonia volatilization, whereas a pH less than 6.5 will result in little ammonia volatilization. Therefore, lowering the pH of the beef feedlot surface may reduce nitrogen volatilization and increase fertilizer value of the manure, which would be especially beneficial during the warm summer months.

According to the U.S. Environmental Protection Agency’s 2019 Inventory of U.S. Greenhouse Gas Emissions and Sinks, 9% of total U.S. greenhouse gas (GHG) emissions are from agriculture. Enteric methane emissions from ruminant animals represent nearly 30% of the agricultural GHG emissions, while manure management contributes 14% of total GHG emissions from the agricultural sector.

There is a lot of interest within agriculture to reduce GHGs. In October 2020, the Innovation Center for U.S. Dairy unveiled the Net Zero Initiative, an industry-wide effort to help U.S. dairy farms of all sizes and geographies implement new technologies and adopt economically viable practices to achieve carbon neutrality, optimize water usage, and improve water quality by 2050. This was followed closely by the National Cattlemen’s Beef Association’s commitment to environmental, economic, and social sustainability by announcing that U.S. cattle production would be climate neutral (or carbon neutral) by 2040. With these big initiatives, all technologies that affect odor or gas emission must also consider the impact on GHGs.

A possible solution

One way livestock producers can reduce these emissions is to apply products to the feedlot surface that can prevent the release of these gases into the air. Aluminum sulfate, also known as alum, is one such product. The poultry industry has successfully used alum for almost 20 years to reduce ammonia emission. Alum works by lowering the pH of the poultry litter, which traps the nitrogen in the litter and keeps it from escaping into the air. This study was designed to see if alum could also work on beef cattle feedlot surfaces to reduce ammonia, hydrogen sulfide, carbon dioxide, nitrous oxide, and methane emissions.

Eight feedlot pens (30 animals per pen) at the U.S. Meat Animal Research Center feedlot were utilized. The pens had a central mound constructed on manure and soil and a concrete apron by the feedbunk. Four pens had 10% alum applied to the 20 feet immediately behind the concrete bunk apron. Four pens did not receive alum.

Samples of the feedlot surface material from each pen were collected one day before alum application, on the day of application, and five, seven, 12, 14, 19, 21, and 24 days post-application. Samples were measured for pH and ammonia, hydrogen sulfide, carbon dioxide, methane, and nitrous oxide emissions.

Addition of alum lowered the pH of feedlot surface material from 8.3 to 4.8 and the pH remained lower in alum-treated pens for 24 days. Although the pH was low, ammonia emissions were only lower at Day 0 and Day 5 for alum-treated pens compared to the pens with no alum treatment. Nitrous oxide emission was not affected by alum treatment.

Carbon dioxide emission was lower for alum-treated pens than non-treated pens from Day 5 until the end of the study, perhaps due to suppressed microbial activity from the lower pH. Hydrogen sulfide emission was higher from alum-treated feedlot surface material compared to nontreated feedlot surface material, likely due to addition of sulfate with alum. Methane emission was also higher in alum-treated pens than nontreated pens. This may be because the alum-treated pens appeared wetter, which creates an environment that produces methane.

More work needed

The limited reduction in ammonia, along with increased hydrogen sulfide and methane emission, indicates that alum is not a suitable amendment to reduce emissions from beef feedlot surfaces. Future research will evaluate the use of aluminum chloride instead of aluminum sulfate to lower pH of feedlot surface material and retain nitrogen, without adding additional sulfate which is converted to hydrogen sulfide. Additionally, microbial amendments are being evaluated to determine if they can reduce gaseous emissions from the feedlot surface.

This article appeared in the February 2023 issue of Journal of Nutrient Management on pages 8-9. Not a subscriber? Click to get the print magazine.