In their busiest seasons, professional manure applicators are constantly in a race against time to meet the needs of their clients. These farms depend on custom applicators to empty their manure storages and deliver nutrients to the field.

While weather most often dictates an applicator’s schedule, there is leg work that can be done prior to arriving on a farm to make the job go smoother for everyone involved. Rick Martens, who has been a custom manure applicator in Minnesota for more than three and a half decades, shared his pre- and post-application checklist to attendees of the Professional Nutrient Applicators Association of Wisconsin Annual Symposium.

Long before you get there

Martens, who owns Marten’s Manurigation in Mora, Minn., said that there is some information that can be gathered from a customer well in advance, perhaps right after you get the first call from a new contact.

First off, he said to get contact information for the lead person at the farm site. “I would advise you only talk to one person from the farm, not several. Then you have one person making decisions,” he explained.

Obtain the address and location of all fields where manure will be applied. Martens shared that for his business, they keep a laminated list of all customers’ addresses in each one of their trucks for easy access by all employees.

Biosecurity concerns should be addressed, as these can vary from farm to farm. “You want to know about any special requests up front,” he said. “You want to know that you can achieve what they expect you to do.”

Similarly, check with the farmer about any local, county, township, or state ordinances you need to know about, and find out if there are any road weight restrictions. He also said to request a copy of the farm’s manure management plan so it can be followed.

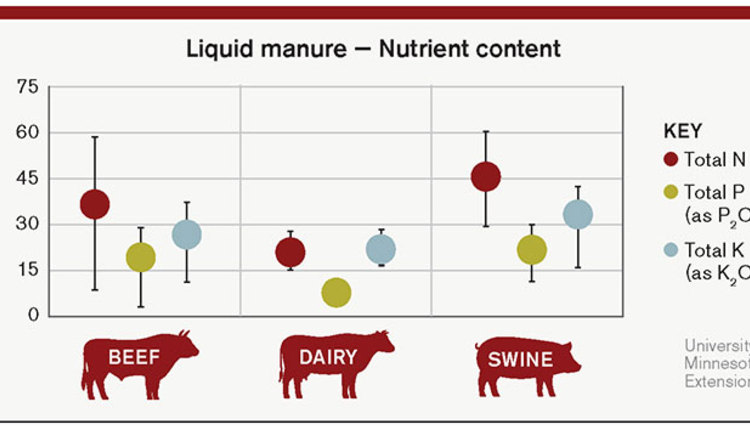

As for the manure, confirm the amount that is supposed to be applied, and ask for any manure test results. Consider the type of manure: whether it’s liquid or solid, what species it came from, and the bedding type and barn style. “Know what you are getting into to, and know if you can handle it or not,” he advised. “Get this information well in advance rather than showing up and finding out you can’t do the job.”

Manure storage type is also a consideration when committing to a job. Is the pit earthen, concrete, or lined? Where are the pump out locations? Are there fences to get through, and what is the slope around the lagoon?

For storage under slatted floor barns, Marten said you must know what the pump access is like. For aboveground pits, ask about pumps and agitation equipment. “You want to know this before you get there,” Martens reiterated. “The way weather has been, saving time is a big issue.”

Ask about the anticipated manure target application rate, the desired timing of application, and if there is any flexibility in timing.

An important side of running a business is the financial aspect. Martens said to review pricing with all customers, which could include a written or verbal contract. Let them know how you charge — per ton, per gallon, or per hour — and if you offer any discounts, such as a reduced fee for immediate payment or for hiring some custom work in an off season. “Be up front about the cost with the farmer,” he said.

Martens said to review field locations, and possibly visit the fields beforehand. Review the route and take note of any shared field roads, road crossings, weight restrictions, or construction detours. Find out if any permits are needed, and if so, who is going to get them. Likewise, decide who is providing the fuel and how much will be available.

By knowing all of this, a custom applicator can make necessary plans for equipment and personnel requirements.

“These are all things we can do before we get to the farm, maybe before we even get into the manure hauling season,” he said. “That way, when you get to the farm, you can hit the ground running and keep rolling.”

On the way

As application day for a farm approaches, Martens said to confirm the date with the farm site supervisor and make sure their fields are ready. Also keep an eye on weather predictions. “We have to know what the weather is doing,” he said.

A manure applicator must determine which farm to go to first. Maybe there’s a farm that you really want to get done, but they will be planting corn silage on the fields where you are spreading, versus a neighbor who needs to grow grain corn. “Sometimes you have to make those hard decisions about who’s the most important at the time,” Martens said.

Ask about any wells, ditches, tile inlets, or waterways where application should be avoided. Inquire about any unusual characteristics of the field.

Martens said this is the time to make sure your equipment is ready to go. Walk around and look at tires, lights, hitch pins, and so forth. Investigate any cracks, dents, and missing or broken pieces. Check lubrication fluids and oil levels, and keep up on the maintenance of all tractors, trucks, and pumps.

Make it a habit to look at a piece of equipment every time you walk by it, Martens said. “Be diligent about this, because you might prevent an accident or downtime later on,” he noted.

Get the job done

Upon arrival, contact the site manager to confirm acres, rates, and field locations. Review the manure management plan with all crew members. “We enter so many unique situations,” he said. “Everyone on the crew has to be up to speed.”

Ask the farmer about any speed or dust restrictions on the roads, and if there are any fences or obstacles (bulls, for example) on the farm. He said to be aware of residential areas, people, and especially children. Rather than driving right by the farmer’s house with every load, consider another path if there are young children in the area.

As for your team, Martens said, “Communicate, communicate, communicate.” Talk about maintenance needs, leaks, unusual smells or sounds, or anything out of the ordinary. “If something doesn’t seem right, it probably isn’t,” he said.

During application, monitor the overall rate and put someone in charge of collecting manure samples.

“Is the farmer getting what he paid for?” Martens asked rhetorically. “He’s paying you to make sure the nutrients are getting in the field, and we have to hit that target rate.”

Before you leave

When the job is done and it is time to move on to the next site, prepare for mobilization. Martens said to clean equipment as appropriate and walk about the equipment to check everything over. Also evaluate the work site for garbage, mud, or manure spills.

“After we are done with a site, we want to make it look decent,” he said. “The reputation of the company is how you leave the site when it’s all said and done.” A good reputation

is how you get repeat customers, and Martens said it is important for employees to know the value of reputation.

When application is complete, prepare the bill and follow up with the site supervisor. Martens said this is a good time to ask the farmer if they have any questions or concerns. “That lets them know you care about the job you do,” he said.

Being prepared for a job is not only important for customer relations. The items on this checklist could also be critical for the future of your business. Martens said he once asked two of his employees, “If something happened to me, could you finish the season?” Their response was that they could get to the end of the day.

“We (as applicators and business owners) do so many things we don’t even think about, and our employees may not see those things,” he explained. Documenting this information helps keep your business running smoothly and prepares you to do your job when Mother Nature gives the green light.

This article appeared in the August 2020 issue of Journal of Nutrient Management on pages 20 and 21.

Not a subscriber? Click to get the print magazine.